In the world of modern manufacturing, precision, speed, and complexity are no longer conflicting goals but expected standards. At the heart of this revolution is a technology that has fundamentally transformed how we create everything from life-saving medical implants to critical aerospace components: Computer Numerical Control (CNC) machining. As a leader in rapid prototyping and on-demand manufacturing, we at Boen Rapid witness its power daily. This article explores the transformative impact of CNC machining and how it is shaping the future of production.

This Article

• What Exactly Constitutes Computer Numerical Control (CNC) Machining?

• How Does the CNC Machining Process Unfold from Design to Part?

• Which Core Advantages Make CNC Machining Indispensable?

• How Does CNC Machining Compare to Additive Manufacturing?

• Where is CNC Machining Making the Biggest Impact?

• Why Partner with Boen Rapid for Your CNC Machining Needs?

What Exactly Constitutes Computer Numerical Control (CNC) Machining?

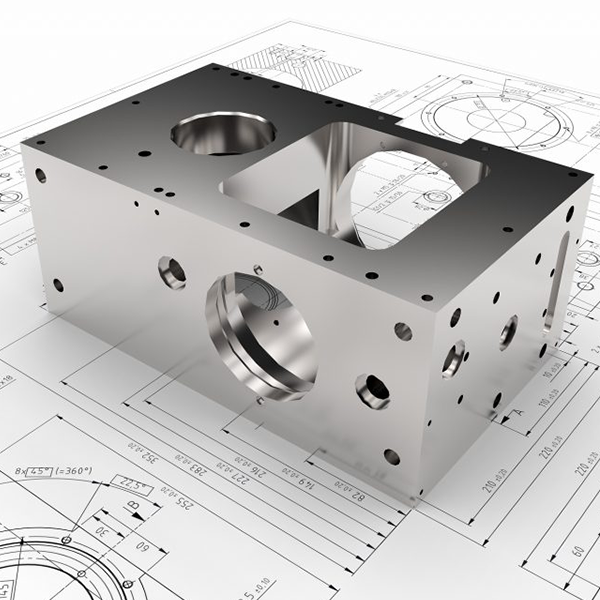

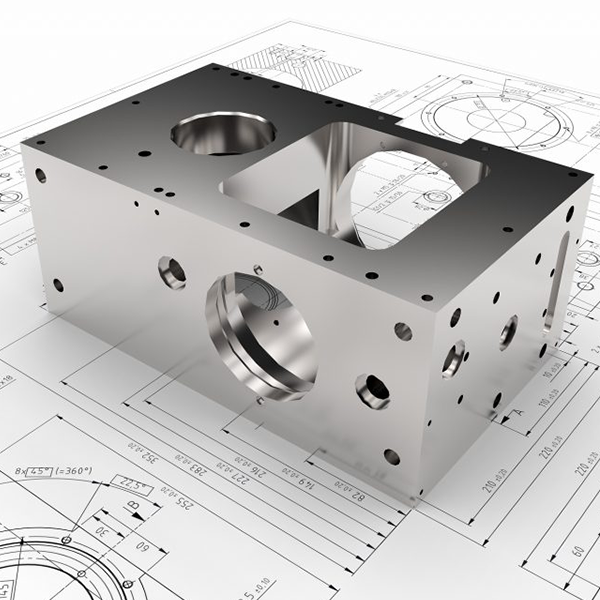

At its core, CNC machining is a subtractive manufacturing process that uses computer-controlled machinery to remove material from a solid block (known as a blank or workpiece) to create a final part. Unlike manual machining, which relies on the hands-on skill of an operator for every cut and turn, CNC machining automates this process with unparalleled accuracy.

The "language" of CNC is a computer program, often written in G-code, which dictates the tool's movements, speed, feed rate, and other critical parameters. A computer sends these precise instructions to the machine—be it a mill, lathe, or router—which then executes the commands flawlessly. This digital control eliminates the potential for human error, ensuring that every part produced is a perfect replica of the digital design, time and time again.

How Does the CNC Machining Process Unfold from Design to Part?

The journey from a digital concept to a physical, high-precision component is a systematic and streamlined process. At Boen Rapid, our expert engineers and technicians guide your project through every stage to ensure optimal results.

1. CAD Model Creation: The process begins with a 2D or 3D Computer-Aided Design (CAD) model. This is the digital blueprint for the final part. Our clients provide us with their design files, which our team reviews for manufacturability.

2. CAM Programming: The CAD file is then imported into Computer-Aided Manufacturing (CAM) software. Here, our programmers strategize the most efficient toolpaths, select the appropriate cutting tools, and set the machine speeds and feeds. The CAM software then generates the G-code that will command the CNC machine.

3. Machine Setup: A skilled technician prepares the CNC machine. This involves securely mounting the workpiece onto the machine bed and loading the necessary cutting tools into the machine's magazine. They then calibrate the machine and tools to ensure perfect alignment.

4. Execution: With the program loaded and the machine set up, the machining process begins. The machine automatically executes the G-code, precisely cutting, drilling, turning, and milling the material to shape the final part. The process is monitored to ensure everything proceeds according to plan.

This seamless integration of digital design and physical production is what makes CNC machining a cornerstone of modern manufacturing, enabling rapid and reliable part creation.

Which Core Advantages Make CNC Machining Indispensable?

The widespread adoption of CNC machining across industries is no accident. It offers a suite of powerful benefits that traditional manufacturing methods simply cannot match.

Unmatched Precision and Repeatability

Computers operate with a level of precision that is superhuman. Our advanced CNC machines can achieve tolerances as tight as ±0.005mm, ensuring that even the most intricate features of a part are perfectly formed. Furthermore, this precision is repeatable across thousands of units, guaranteeing consistency from the first part to the last—a critical requirement for industries like medical and aerospace.

Incredible Speed and Efficiency

Once a program is created and verified, a CNC machine can run continuously with minimal supervision. This automation dramatically reduces cycle times compared to manual processes. For businesses needing parts quickly, like those in the rapid prototyping phase, the speed of CNC machining is a game-changer. At Boen Rapid, our name reflects our commitment to this advantage, delivering high-quality parts on accelerated timelines.

Capability for Complex Geometries

Modern 3-axis, 4-axis, and especially 5-axis CNC machines can create incredibly complex shapes and features that would be difficult or impossible to produce manually. 5-axis machining allows the cutting tool to approach the workpiece from five different directions simultaneously, enabling the creation of intricate curves, undercuts, and multifaceted designs in a single setup, which increases both accuracy and efficiency.

Vast Material Compatibility

CNC machining is not limited to a single type of material. Its subtractive nature allows it to work with a huge range of production-grade metals and plastics, each offering unique mechanical properties. This versatility makes it the ideal choice for creating functional prototypes and end-use parts across diverse applications.

| Common Materials Used in Our CNC Machining Services |

|

Metals | Aluminum (6061, 7075), Stainless Steel (303, 304, 316L), Steel, Brass, Copper, Titanium | High strength, durability, conductivity, corrosion resistance |

|

|

Plastics | ABS, PC (Polycarbonate), POM (Delrin), PMMA (Acrylic), Nylon, PEEK | Lightweight, electrical insulation, chemical resistance, wear resistance |

|

|

How Does CNC Machining Compare to Additive Manufacturing?

A common question is how CNC machining (subtractive) stacks up against 3D printing (additive manufacturing). While both are powerful digital manufacturing tools, they have distinct strengths. At Boen Rapid, we offer both services, allowing us to recommend the best process for your specific needs. Understanding their differences is key to making the right choice.

| CNC Machining (Subtractive) vs. 3D Printing (Additive) |

|

Process | Material is removed from a solid block. | Material is added layer-by-layer to build a part. |

|

|

Strengths | Superior strength and material properties (solid block), excellent surface finish, extremely tight tolerances. | Can create complex internal geometries and hollow structures, less material waste, ideal for initial form/fit prototypes. |

|

|

Material Selection | Wide range of metals, plastics, and other solid materials. | Primarily plastics and some metals, material properties can differ from bulk material. |

|

|

Best For | High-precision functional parts, structural components, parts requiring excellent mechanical properties. | Complex, lightweight designs, rapid conceptual prototypes, non-structural components. |

|

|

Often, the two technologies are complementary. A project might begin with a 3D-printed prototype to validate a design, followed by CNC machining for the production of strong, functional end-use parts.

Where is CNC Machining Making the Biggest Impact?

The versatility and reliability of CNC machining have made it an essential technology in nearly every major industry. Its ability to produce high-quality, durable parts consistently makes it the go-to solution for demanding applications.

• Aerospace: For creating lightweight, high-strength components like turbine blades, structural brackets, and housings with flawless precision. There is zero room for error in this industry, and CNC delivers.

• Medical: In the production of surgical instruments, custom orthopedic implants (like knee and hip replacements), and components for medical devices, where biocompatibility and perfect accuracy are paramount.

• Automotive: From prototyping new engine blocks and transmission components to manufacturing custom parts for performance vehicles, CNC provides the speed and durability the auto industry requires.

• Consumer Electronics: For machining the sleek metal casings of smartphones, laptops, and other devices, where a perfect fit and premium finish are crucial to the product's success.

Why Partner with Boen Rapid for Your CNC Machining Needs?

Understanding the power of CNC machining is one thing; leveraging it effectively is another. Choosing the right manufacturing partner is critical to the success of your project. At Boen Rapid, we've built our reputation on being that trusted partner.

• Advanced Technology: We invest in state-of-the-art 3, 4, and 5-axis CNC machining centers to handle projects of any complexity and deliver superior results.

• Uncompromising Quality: Our operations are ISO 9001 certified, and we employ a rigorous quality control process, including in-process inspections and final reports, to guarantee your parts meet or exceed specifications.

• Rapid Turnaround: We understand the need for speed. Our streamlined processes, from instant quoting to efficient production scheduling, ensure you get your parts when you need them.

• Expert Team: Our team consists of highly skilled engineers and machinists with deep expertise across a wide range of materials and industries. We provide expert design-for-manufacturability feedback to help you optimize your parts for cost and performance.

• One-Stop Manufacturing Solution: Beyond CNC machining, we offer a comprehensive suite of services including 3D printing, sheet metal fabrication, and injection molding, making us a single-source partner for all your prototyping and production needs.

The age of digital manufacturing is here, and CNC machining is leading the charge. It empowers innovators, engineers, and designers to bring their most ambitious ideas to life with a level of precision and quality that was once unimaginable.

Ready to leverage the power of precision CNC machining for your next project? Contact Boen Rapid today to get a free quote and discover how our expertise can drive your success.