Low-volume CNC manufacturing is a production process that uses Computer Numerical Control (CNC) machines to create between 10 and 10,000 high-quality, end-use parts. It offers a cost-effective alternative to mass production by eliminating the significant upfront investment in hard tooling, such as molds or dies, making it ideal for bringing new products to market faster and with greater design flexibility.

This text explains the critical aspects of short-run CNC production, helping you determine if it is the right fit for your project.

Table of Contents

1. What Exactly is Low-Volume CNC Manufacturing?

2. Why Choose Short-Run Production for Your Project?

3. When is Low-Volume Manufacturing the Ideal Solution?

4. How Does Low-Volume Production Keep Costs Down?

5. Which Materials Can Be Used in Small-Batch CNC Machining?

6. What Design for Manufacturability (DFM) Principles are Crucial?

7. How is Quality Maintained Without Mass Production Tooling?

8. What Industries Benefit Most from This Approach?

9. How Can You Optimize Your Parts for Cost-Effective CNC Machining?

10. What Should You Look for in a Low-Volume Manufacturing Partner?

What Exactly is Low-Volume CNC Manufacturing?

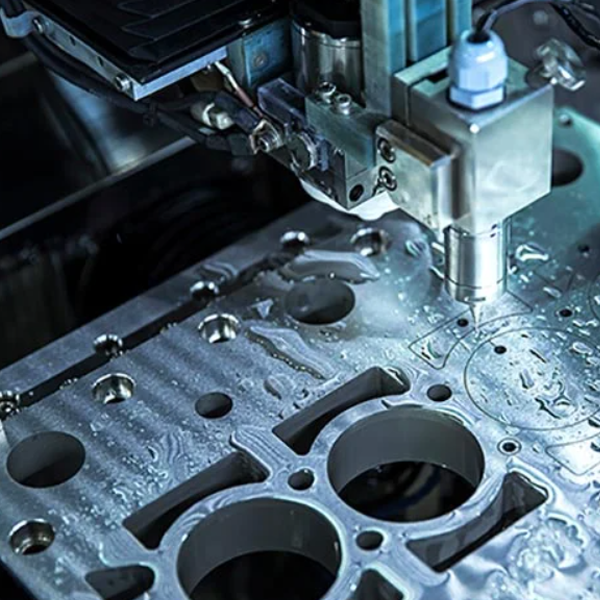

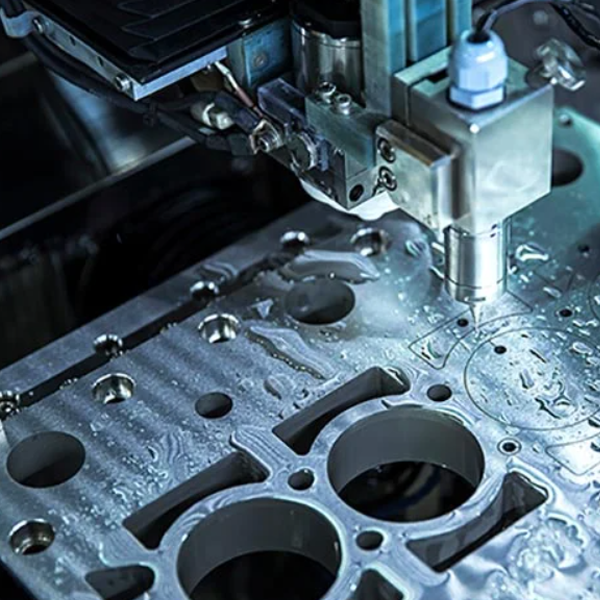

Low-Volume CNC Manufacturing , often called small-batch or short-run production, occupies a strategic middle ground between one-off prototyping and full-scale mass production. It focuses on producing a limited quantity of parts, typically ranging from as few as ten units up to several thousand. This quantity is too large for prototyping methods to be cost-effective but too small to justify the enormous capital expenditure required for traditional mass-production tooling like injection molds or stamping dies.

The process leverages the power of Computer Numerical Control (CNC) machining. Designs are created in CAD (Computer-Aided Design) software and then translated into machine code. This code directs automated cutting tools—such as mills, lathes, and grinders—to remove material from a solid block (a "blank") to create the final part with extreme precision. Because the process is digitally driven, changes can be made by simply editing the CAD file, offering incredible agility that is impossible with fixed tooling.

Why Choose Short-Run Production for Your Project?

Opting for short-run manufacturing provides several powerful strategic advantages that can significantly impact a project's budget, timeline, and ultimate success. It empowers companies to be more agile, responsive, and financially prudent in their product development lifecycle.

Achieve Significant Cost Savings

The most compelling financial benefit is the avoidance of high tooling costs. Injection molding, for example, can require molds that cost tens or even hundreds of thousands of dollars before a single part is produced. Low-volume CNC machining bypasses this entirely. The primary costs are material and machine time, making it economically viable to produce hundreds or thousands of parts without a massive initial investment. This dramatically lowers the barrier to entry for new products and reduces financial risk.

Accelerate Your Time to Market

Speed is a critical competitive advantage. The lead time for creating hard tooling can take months. In contrast, CNC machining for low volumes can be initiated almost immediately after a design is finalized. Parts can be produced and shipped in a matter of days or weeks, not months. This acceleration allows businesses to launch products faster, capture market share, and begin generating revenue sooner. It also enables them to respond swiftly to sudden market opportunities or competitive pressures.

Gain Unmatched Design Flexibility

Low-volume production is not a one-and-done process. Since it doesn't rely on fixed tooling, designs can be easily tweaked and improved between production runs. If initial customer feedback reveals a need for a design change, or if a functional flaw is discovered, the CAD model can be updated, and the next batch will reflect the improvement. This iterative approach minimizes the risk of being locked into a suboptimal design and ensures the final product is truly refined before considering a larger production scale.

When is Low-Volume Manufacturing the Ideal Solution?

Knowing when to leverage small-batch production is key to maximizing its benefits. This manufacturing strategy is not a one-size-fits-all solution but excels in several specific scenarios. It serves as a critical tool for businesses navigating the complexities of product development, market entry, and supply chain management.

One of its most common applications is as a bridge to production. After a handful of prototypes have validated a concept, a low-volume run of several hundred or a few thousand units can be used for rigorous real-world testing, regulatory certification, or an initial pilot launch. This step verifies manufacturability and market demand before committing to expensive mass-production tooling, acting as a crucial risk-mitigation stage.

It is also the perfect solution for highly customized or niche market products. For industries like aerospace, medical devices, or high-performance automotive, where parts are often specific to an application and not needed in massive quantities, low-volume CNC is the default choice. Additionally, it is invaluable for managing fluctuating or uncertain market demand. Instead of producing a large inventory that may never sell, companies can produce parts on-demand, aligning production directly with actual sales and minimizing warehousing costs and waste.

How Does Low-Volume Production Keep Costs Down?

The cost-effectiveness of low-volume manufacturing stems from its fundamentally different economic model compared to mass production. While a high-volume process like injection molding may have a very low per-unit cost, that price is only achievable after the astronomical tooling costs are amortized over hundreds of thousands of units. Small-batch CNC machining eliminates this initial financial hurdle, making the total project cost far lower for smaller quantities.

The cost structure is heavily influenced by digital workflows. Modern manufacturing partners use sophisticated software to automate quoting, analyze design manufacturability, and optimize machine toolpaths. This reduces the need for manual intervention, minimizes setup time, and ensures the machine runs as efficiently as possible. Costs are therefore directly related to tangible factors: the complexity of the part (which dictates machine time), the type of material chosen, and the number of units in the batch. As the batch size increases, the initial setup costs are spread across more parts, leading to a reduction in the per-unit price.

Metric | Prototyping (1-10 Units) | Low-Volume CNC (10-10,000 Units) | Mass Production (>100,000 Units) |

Tooling Cost | None | None | Very High ($10k - $100k+) |

Per-Unit Cost | High | Moderate to Low | Very Low |

Lead Time | Very Fast (Days) | Fast (Weeks) | Very Slow (Months) |

Design Flexibility | Very High | High | Very Low / None |

Which Materials Can Be Used in Small-Batch CNC Machining?

A significant advantage of CNC machining for low-volume production is the ability to use production-grade materials from the very beginning. Unlike some additive manufacturing processes that are limited to specific polymers, CNC can shape virtually any machinable material. This means that parts produced in small batches can have the exact mechanical, thermal, and chemical properties required for end-use applications.

This provides engineers with a vast selection of materials to fit their specific needs, ensuring parts are not just visually accurate but also functionally robust. Common material categories include:

• Plastics: Versatile and cost-effective options like ABS, Polycarbonate (PC), Nylon, Acrylic (PMMA), and high-performance polymers like PEEK and Ultem are readily available for machining.

• Metals: A wide array of metals can be machined, from lightweight Aluminum alloys (e.g., 6061, 7075) and cost-effective steels to corrosion-resistant Stainless Steel (e.g., 303, 304, 316), Brass, Copper, and high-strength Titanium.

The ability to use these final materials during the low-volume stage is crucial for meaningful functional testing. It ensures that test results are accurate and that the parts will perform as expected in the hands of customers.

What Design for Manufacturability (DFM) Principles are Crucial?

While CNC machining is highly capable, designing parts with manufacturability in mind is essential for controlling costs and ensuring quality. Design for Manufacturability (DFM) is a set of principles aimed at making parts easier and more efficient to produce. Applying DFM can drastically reduce machine time, which is a primary cost driver in CNC.

Key DFM considerations for CNC machining include simplifying geometry wherever possible, as complex curves and surfaces require more advanced and time-consuming machining strategies. Designers should aim to use standard drill sizes and create generous corner radii (ideally larger than the cutter's radius) to allow for faster tool movement. Deep, narrow pockets should be avoided, as they require long, fragile tools that are prone to breaking and must run slowly. Finally, specifying only the necessary tolerances is critical; overtightening tolerances on non-critical features can increase machining time and inspection costs exponentially without adding functional value.

How is Quality Maintained Without Mass Production Tooling?

A common misconception is that the quality and consistency of mass-produced parts from a single mold or die are inherently superior. However, modern low-volume CNC manufacturing achieves exceptional quality through a combination of machine precision and rigorous process control. The inherent accuracy of today's multi-axis CNC machines can produce parts with extremely tight tolerances, often exceeding what is possible with molding.

Consistency across a batch is ensured by a robust Quality Management System (QMS). This begins with initial design validation and continues with in-process inspections. Critical dimensions are checked periodically throughout the production run to ensure the process remains within specification. After machining, parts undergo a final quality control check using precision measurement tools like digital calipers, micrometers, and Coordinate Measuring Machines (CMMs). This systematic approach guarantees that the first part off the machine is identical to the last, ensuring reliability and performance for every component delivered.

What Industries Benefit Most from This Approach?

The flexibility, speed, and cost-effectiveness of short-run CNC production make it a valuable asset across a diverse range of high-tech industries. Any sector that requires high-precision, functional parts for testing, customization, or niche markets is a prime candidate.

• Medical Devices: For creating prototypes of surgical instruments, custom implants, and enclosures for diagnostic equipment, using biocompatible and sterilizable materials.

• Aerospace & Defense: For manufacturing lightweight components, complex prototypes for wind-tunnel testing, and flight-certified parts in limited quantities.

• Automotive: Ideal for producing custom parts for performance racing, components for vehicle restoration, and pre-production runs to test new designs before committing to mass tooling.

• Robotics & Automation: For fabricating custom jigs, fixtures, end-effectors, and structural components that need to be strong, precise, and often unique to a specific automated system.

• Consumer Electronics: For creating high-fidelity prototypes and first-run enclosures for market testing, as well as limited-edition or luxury product lines.

How Can You Optimize Your Parts for Cost-Effective CNC Machining?

Engineers and designers can directly influence the cost of their CNC-machined parts by making smart design choices. Optimizing a part for machining efficiency is one of the most effective ways to reduce costs without compromising function. A few practical tips can lead to significant savings.

Firstly, avoid thin walls and very deep pockets. Thin walls are susceptible to vibration and warping during machining, forcing the machine to run slower for a good finish. Deep pockets require long, slender tools that are less rigid and must cut material at a slower rate. Secondly, try to minimize the number of machine setups. If a part can be designed so all features can be machined from one or two sides, it eliminates the time and potential for error associated with repositioning the part. Lastly, be deliberate about surface finish requirements. A standard, as-machined finish is the most cost-effective. Requesting smoother or polished finishes only on surfaces where it is functionally or aesthetically necessary can save considerable time and expense.

What Should You Look for in a Low-Volume Manufacturing Partner?

Selecting the right manufacturing partner is just as critical as the design of the part itself. The ideal partner acts as more than just a supplier; they become an extension of your engineering team, providing guidance and expertise to ensure your project is a success. When evaluating potential partners, there are several key attributes to consider.

A top-tier partner like Boen Rapid will offer comprehensive engineering support and DFM feedback, helping you optimize your design for cost and quality before production begins. They should also provide access to a wide range of materials and finishing options, giving you the flexibility to produce parts that meet your exact specifications. Look for a company with transparent, fast, and detailed quoting processes, so you have a clear understanding of costs and lead times upfront. Most importantly, a trustworthy partner must have a proven and documented quality control process, including certifications like ISO 9001, to guarantee that every part you receive is flawless and meets your standards. At Boen Rapid, we combine state-of-the-art CNC technology with a dedicated team of experts to deliver superior-quality parts, on time and on budget, turning your innovative designs into reality.