Combining rapid prototyping with CNC production accelerates time-to-market for custom mechanical components by using a single, highly accurate manufacturing process for both functional prototypes and end-use parts. This powerful synergy eliminates the lengthy and costly transition to production tooling, enabling rapid design validation and a direct, scalable path to low-volume manufacturing with production-grade materials from day one.

Table of Contents

• What is the Synergy Between Rapid Prototyping and CNC Production?

• The Prototyping Phase: Why Choose CNC Machining?

• How Does This Combination Drastically Reduce Time-to-Market?

• The Strategic Role of CNC in Low-Volume Manufacturing

• Navigating the Process: From Digital Design to Physical Component

• What Materials Are Best for CNC-Driven Rapid Manufacturing?

• Key Industries Benefiting from this Integrated Approach

• Additive vs. Subtractive: When to Use Which Method?

• Selecting the Right Manufacturing Partner for Success

• What Are the Critical Considerations for Design for Manufacturability (DFM)?

What is the Synergy Between Rapid Prototyping and CNC Production?

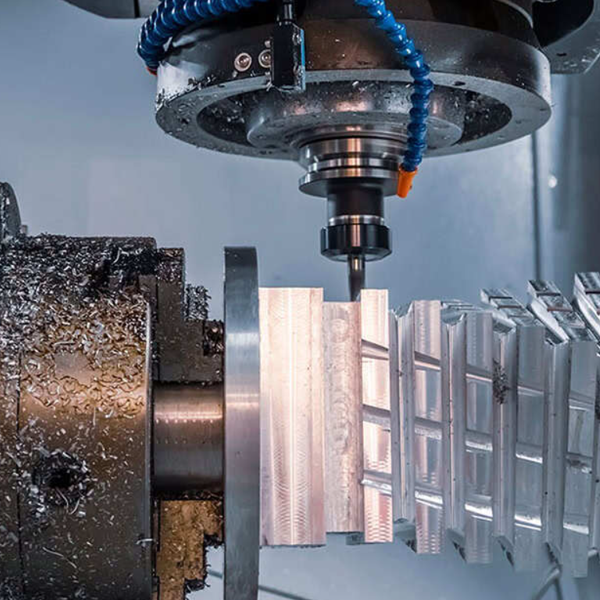

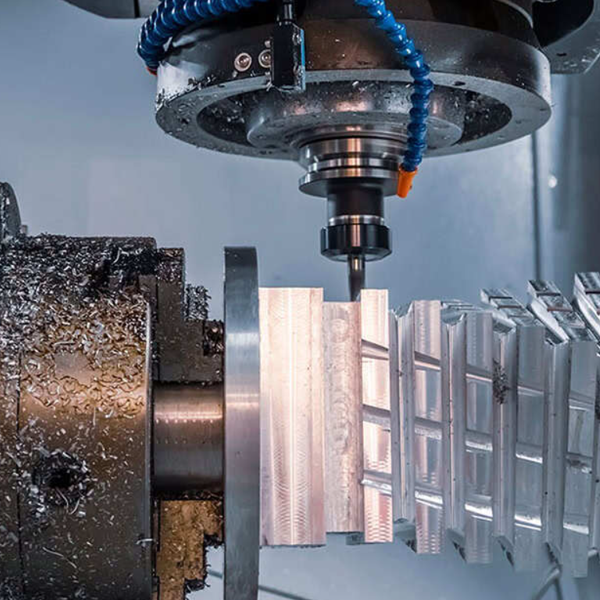

The integration of rapid prototyping and CNC production represents a fundamental shift in modern product development. It creates a seamless continuum from initial concept validation to final part production. At its core, this approach leverages the same foundational technology—Computer Numerical Control (CNC) machining—for multiple stages of the development cycle. This eliminates discrepancies that often arise when switching between different manufacturing methods for prototyping and production.

Rapid prototyping is the practice of quickly fabricating a scale model or a functional assembly using three-dimensional computer-aided design (CAD) data. While often associated with additive methods like 3D printing, it also encompasses subtractive methods like CNC machining. The goal is to test form, fit, and function early and often. CNC production is a subtractive manufacturing process that uses computer-controlled machines to remove material from a solid block (a blank) to create a highly precise, final-spec part.

The synergy arises when CNC machining is used for both prototyping and production. A prototype machined from the intended end-use material provides far more valuable performance data than a 3D-printed equivalent in a dissimilar polymer. When that prototype is validated, the very same CNC programs, with minor refinements, can be used to produce the first batch of sellable products. This creates an incredibly efficient and fast pathway from an idea to a market-ready component.

The Prototyping Phase: Why Choose CNC Machining?

While 3D printing offers incredible speed for early-stage conceptual models, CNC machining provides distinct advantages for creating high-fidelity, functional prototypes. For mechanical components that must withstand physical stress, meet tight tolerances, or interact with other parts, a CNC-machined prototype is often the superior choice. It moves beyond simple visual representation to deliver true performance validation.

Unmatched Material Fidelity and Properties

The most significant benefit of using CNC for prototyping is the ability to use production-grade materials from the very beginning. If your final component needs to be made from 6061 aluminum, stainless steel, or PEEK, you can prototype with that exact material. This is crucial for accurate testing of mechanical properties such as tensile strength, heat resistance, chemical compatibility, and wear characteristics. A 3D-printed part, even from an advanced engineering polymer, cannot perfectly replicate the isotropic strength and thermal behavior of a solid metal block. Using the real material provides data you can trust, preventing late-stage failures when the design transitions to production.

Superior Accuracy and Surface Finish

CNC machining is renowned for its exceptional precision and ability to achieve very tight tolerances, often within ±0.001 inches (0.025 mm) or better. This level of accuracy is vital for parts that require a precise fit in a larger assembly. Furthermore, the surface finish of a machined part is typically much smoother and more representative of a final product than that of a raw 3D print. A quality surface finish is not just cosmetic; it can be critical for sealing surfaces, reducing friction, and ensuring proper fluid dynamics. This allows for realistic testing of seals, bearings, and mating components.

How Does This Combination Drastically Reduce Time-to-Market?

Speed is the ultimate competitive advantage in product development. The fusion of CNC-based prototyping and production directly targets the most significant delays in the traditional manufacturing workflow, compressing timelines from months to weeks.

Seamless Transition from Prototype to Production

The traditional path involves prototyping with one method (e.g., 3D printing) and then re-engineering the part for a different production method (e.g., injection molding or casting). This transition introduces significant delays, risks, and redesign loops. When using CNC for both stages, the transition is almost nonexistent. Design feedback from the machined prototype can be used to tweak the CAD file, and a new part can often be machined the same day. Once the design is finalized, the process is already proven. There is no need to develop new tooling, which is often the longest lead-time item in a project.

Eliminating the Need for Production Tooling

Creating hard tooling, such as injection molds or casting dies, is a major investment of time and capital, often taking 8-16 weeks or more. This process is inflexible; any design change requires expensive and time-consuming tool modifications. The CNC machining approach bypasses this "tooling gap" entirely. It allows a company to go directly from a validated prototype to producing hundreds or even thousands of units. This is ideal for initial product launches, bridge production while tooling is made, or for products with a limited lifecycle where high-volume tooling is never justified.

The Strategic Role of CNC in Low-Volume Manufacturing

CNC machining is not just for one-off prototypes; it is an incredibly effective and economical solution for low-to-mid volume production runs. This capability, often called "bridge production" or "on-demand manufacturing," offers immense strategic flexibility for businesses. It enables companies to get products into customers' hands and generate revenue while more traditional high-volume methods are being prepared, or it can serve as the primary production method for specialized, high-value products.

For quantities ranging from a few dozen to several thousand units, CNC machining is often more cost-effective than investing in expensive tooling. It allows for continuous design improvement even after the product has launched. If customer feedback suggests a minor design tweak, the CAD model can be updated, and the next batch of parts will reflect the change immediately. This agility is impossible with hard tooling. Companies like BoenRapid specialize in this flexible production model, providing high-quality machined parts on demand to support agile product development and inventory management.

Navigating the Process: From Digital Design to Physical Component

The workflow for turning a digital concept into a tangible, precision-machined part is straightforward and highly efficient. Understanding these steps helps in planning project timelines and collaborating effectively with a manufacturing partner.

The entire process is digitally driven, which minimizes human error and maximizes repeatability. Each step builds upon the previous one, ensuring that the final part perfectly matches the approved design intent.

| Stage | Description |

1. 3D CAD Design | The process begins with a detailed 3D CAD model. This file contains all geometric information about the part, including its dimensions, features, and complex surfaces. Formats like STEP, IGS, or X_T are standard. |

|

2. DFM Analysis & Quoting | The CAD file is analyzed for manufacturability (DFM). A manufacturing partner will review the design for potential issues like deep pockets, thin walls, or difficult-to-machine features and provide a quote. |

|

3. CAM Programming | Once the design is approved, a programmer uses CAM (Computer-Aided Manufacturing) software to generate the toolpaths—the precise G-code instructions that will guide the CNC machine's cutting tools. |

|

4. Machine Setup & Machining | A block of the chosen material is secured in the CNC machine. The operator loads the program, sets up the tools, and initiates the automated machining process. The machine precisely cuts away material to reveal the final part. |

|

5. Quality Inspection & Finishing | The finished part is removed, cleaned, and inspected using precision measurement tools like calipers and CMMs to ensure it meets all dimensional specifications. Post-processing steps like deburring, anodizing, or painting are then completed. |

|

What Materials Are Best for CNC-Driven Rapid Manufacturing?

One of the primary strengths of CNC machining is its vast material compatibility. Unlike many other prototyping processes that are limited to specific polymers, CNC can shape nearly any solid material, from soft plastics to hardened tool steels and exotic superalloys.

Metals are the most common choice for functional mechanical components due to their strength, durability, and thermal properties.

• Aluminum Alloys (e.g., 6061, 7075): Excellent strength-to-weight ratio, good thermal conductivity, and corrosion resistance. Ideal for a wide range of applications from aerospace brackets to consumer electronics housings.

• Stainless Steel (e.g., 303, 304, 316L): High strength, exceptional corrosion resistance, and sterilizable. Widely used in medical devices, food processing equipment, and marine applications.

• Carbon & Alloy Steels: Offer high strength and wear resistance, often at a lower cost than stainless steel. Can be heat-treated for increased hardness.

• Brass and Copper: Valued for their electrical conductivity and corrosion resistance. Brass is also easily machinable.

Plastics offer a lightweight and often lower-cost alternative for a variety of applications.

• ABS: A common thermoplastic with good impact resistance and mechanical properties.

• Polycarbonate (PC): High impact strength and transparency, often used for optical components or durable housings.

• Nylon: Excellent wear resistance and low-friction properties, making it suitable for gears and bearings.

• PEEK: A high-performance polymer with exceptional mechanical strength, chemical resistance, and high-temperature stability, often used as a metal replacement in demanding environments.

Key Industries Benefiting from this Integrated Approach

The speed and fidelity of combined CNC prototyping and production are a game-changer across numerous sectors where innovation and reliability are paramount.

In the aerospace and defense industry, parts must meet extreme performance and safety standards. CNC machining with certified materials allows for the creation of flight-worthy components for functional testing and even for final use in drones, satellites, and aircraft interiors. For the medical device sector, the ability to machine prototypes from biocompatible materials like 316L stainless steel or PEEK is critical for creating surgical instruments, implants, and diagnostic equipment that can be properly tested and sterilized.

The fast-paced automotive world leverages this approach for everything from custom jigs and fixtures on the assembly line to performance engine components and suspension parts for testing and motorsports. Finally, in consumer electronics, CNC machining is used to create the high-quality aluminum and plastic enclosures for laptops, smartphones, and audio equipment, allowing brands to achieve a premium look and feel while rapidly iterating on designs.

Additive vs. Subtractive: When to Use Which Method?

Choosing between additive manufacturing (3D printing) and subtractive manufacturing (CNC machining) is not an "either/or" decision. The smartest development teams use both, leveraging each method's strengths at the appropriate stage.

Use 3D Printing When:

• You are in the very early concept stage and need a quick, low-cost physical model to check basic form and ergonomics.

• The part geometry is extremely complex, with internal lattice structures or features that are impossible to machine.

• Speed is the absolute top priority, and material properties are secondary.

Use CNC Machining When:

• You need to test the mechanical performance of a part using the actual production material.

• Tight tolerances and a superior surface finish are critical requirements.

• The prototype needs to withstand significant physical loads, high temperatures, or chemical exposure.

• You are creating the first few units of a product and want them to be identical to the final version.

A hybrid strategy is often the most effective. Use 3D printing for quick, iterative sanity checks, then commit to a CNC-machined prototype for final validation before moving to low-volume production.

Selecting the Right Manufacturing Partner for Success

The success of your product development hinges on the capabilities and expertise of your manufacturing partner. A partner is more than just a vendor; they are an extension of your engineering team. When evaluating potential partners, look for a provider that offers a comprehensive suite of services under one roof.

Key criteria include a deep understanding of both rapid prototyping and full-scale CNC production. This ensures they can guide your project smoothly from one stage to the next. A partner with extensive material knowledge, advanced multi-axis CNC machines, and robust quality control systems is essential. Look for certifications like ISO 9001, which demonstrate a commitment to quality. A partner like BoenRapid , with proven expertise in machining complex geometries and providing a range of finishing services, can manage the entire manufacturing workflow, offering valuable DFM feedback and ensuring your components are delivered on time and to spec.

What Are the Critical Considerations for Design for Manufacturability (DFM)?

Designing a part that is efficient and cost-effective to machine is a skill known as Design for Manufacturability (DFM). Applying DFM principles early in the design phase can significantly reduce production costs and lead times without compromising functionality. It involves thinking like a machinist while you design.

Some core DFM considerations for CNC machining include standardizing corner radii to match common tool diameters, avoiding deep and narrow pockets that require long, fragile tools, and designing features with sensible tolerances—over-tolerancing a non-critical feature adds unnecessary cost and time. Other factors include minimizing the number of machine setups required by designing features to be accessible from one or two directions, and choosing materials that balance performance needs with machinability. Collaborating with your manufacturing partner on DFM review is one of the highest-value activities in the product development process, ensuring your design is optimized for both performance and production efficiency.