Rapid prototyping is the swift fabrication of a physical part, model, or assembly using 3D computer-aided design (CAD) data. Its essential role in modern product development is to dramatically accelerate innovation cycles by enabling designers and engineers to quickly create tangible models for testing, validation, and feedback. This process is fundamental to achieving a faster speed to market, as it allows for rapid iterations, early detection of design flaws, and significant reductions in development costs and risks.

Table of Contents

· What is Rapid Prototyping?

· Why is Accelerating Speed to Market a Critical Advantage?

· How Does Rapid Prototyping Revolutionize the Development Cycle?

· Key Rapid Prototyping Technologies Driving Innovation

· The Tangible Benefits Beyond Just Speed

· Integrating Rapid Prototyping into Your Workflow

What is Rapid Prototyping?

Rapid prototyping refers to a group of advanced manufacturing techniques used to create a scale model of a physical part or assembly quickly and efficiently. Unlike traditional subtractive methods that could take weeks or months, rapid prototyping leverages digital CAD files to generate tangible objects, often in a matter of hours or days. This isn't limited to a single technology but encompasses a suite of processes, each with unique strengths, including 3D printing, CNC machining, and vacuum casting.

The core principle is the ability to transform a digital concept into a physical object that can be held, tested, and evaluated. This physical representation is invaluable, as it moves a project from the theoretical realm of on-screen designs into the practical reality of the physical world. It allows teams to assess ergonomics, fit, form, and sometimes even function, long before committing to expensive and time-consuming production tooling. This iterative "build and learn" approach is the cornerstone of agile product development.

Why is Accelerating Speed to Market a Critical Advantage?

In today's hyper-competitive global marketplace, the window of opportunity for a new product is often fleeting. Being the first to market can establish brand leadership, capture significant market share, and set the industry standard. Speed to market is the measurement of time it takes from product conception to its availability for sale. Reducing this timeline is not just a logistical goal; it is a primary strategic objective that directly impacts profitability and long-term business viability.

Gaining a Competitive Edge

Companies that can iterate and launch faster than their rivals hold a decisive advantage. A swift development process allows a business to respond more dynamically to emerging market trends, technological advancements, or shifts in consumer behavior. While competitors are still in the early design or tooling phases, an agile company can already have a product in the hands of customers, gathering real-world data and building brand loyalty. This first-mover advantage creates a barrier to entry for latecomers, who are then forced to play catch-up.

Maximizing Market Opportunity and ROI

Every day a product spends in development is a day it is not generating revenue. A shorter development cycle means an earlier start to sales, leading to a quicker return on investment (ROI). This is particularly critical for products with short life cycles, such as consumer electronics or seasonal goods. Furthermore, launching a product sooner extends its revenue-generating lifespan before it becomes obsolete or is superseded by a next-generation version. Efficiently moving through the development pipeline directly translates to improved financial performance.

How Does Rapid Prototyping Revolutionize the Development Cycle?

The traditional product development model was linear and fraught with long delays. A design was created, sent out for tooling, and weeks later a prototype would arrive. If any issues were found, this entire lengthy process would have to be repeated. Rapid prototyping shatters this old paradigm by introducing a fast, cyclical, and iterative workflow.

From Weeks to Days: Compressing the Design-Test Loop

The most profound impact of rapid prototyping is its ability to drastically compress the design-build-test-learn loop. What once took weeks of waiting for a machined or molded part can now be accomplished overnight with technologies like 3D printing. An engineer can modify a CAD file in the afternoon and have a physical part on their desk the next morning. This incredible speed allows for multiple iterations in the same amount of time it would have taken to produce a single prototype traditionally. This philosophy of "fail fast, fail cheap" encourages experimentation and innovation by lowering the penalty for design errors.

Facilitating Early and Frequent Feedback

Digital models are useful, but nothing replaces the value of a physical object. Rapid prototypes enable stakeholders—including designers, engineers, marketing teams, and even potential customers—to provide tangible feedback early in the process. A marketing manager can assess the look and feel of a product, an engineer can test the fit and assembly of mating parts, and a focus group can evaluate its ergonomics. This early, cross-functional feedback is critical for aligning the product with both market expectations and manufacturing capabilities, preventing costly changes down the line.

Key Rapid Prototyping Technologies Driving Innovation

The effectiveness of rapid prototyping is powered by a diverse set of manufacturing technologies. Companies like Boen Rapid offer a comprehensive suite of services, allowing product developers to choose the perfect method based on their specific needs for speed, material properties, fidelity, and cost.

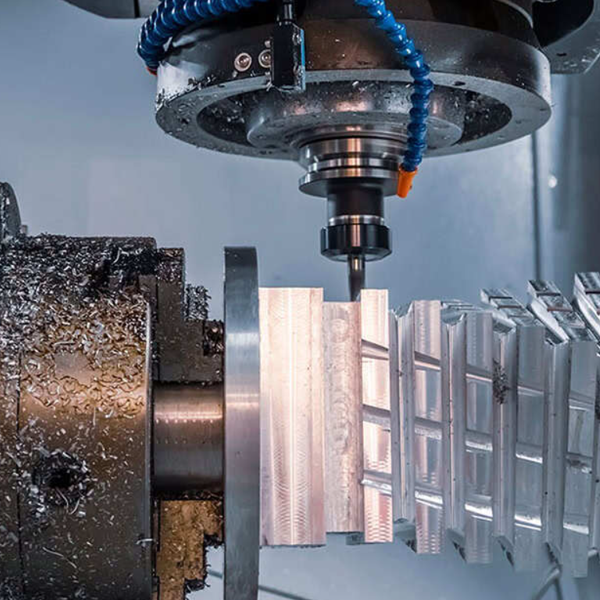

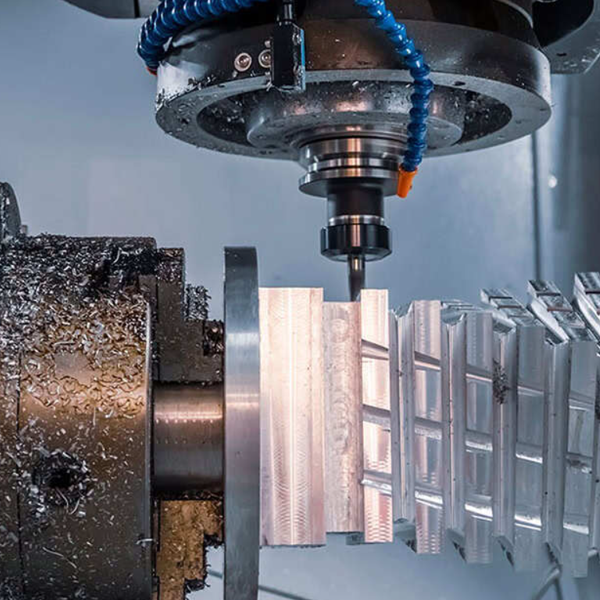

CNC Machining: Precision and Real-Material Prototypes

Computer Numerical Control (CNC) machining is a subtractive process where a block of material is precisely cut into a desired shape by a computer-controlled tool. Its primary advantage for prototyping is the ability to use production-grade materials like aluminum, steel, brass, and engineering plastics. This allows for the creation of high-fidelity prototypes that possess the true mechanical properties, strength, and surface finish of the final product. CNC machining is ideal for functional testing, stress analysis, and creating parts that demand tight tolerances and superior material performance.

3D Printing (Additive Manufacturing): Speed and Complexity

3D Printing, or additive manufacturing, builds objects layer by layer directly from a CAD file. Technologies like Stereolithography (SLA) and Selective Laser Sintering (SLS) offer unparalleled speed for producing complex geometries that would be difficult or impossible to create with traditional methods. SLA is known for creating parts with a very smooth surface finish, excellent for visual models, while SLS produces strong, functional parts from nylon and other polymers. This technology is the go-to choice for initial concept models, form and fit checks, and creating intricate internal features.

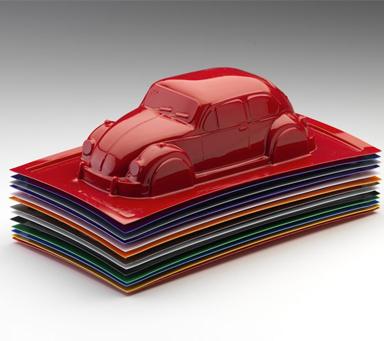

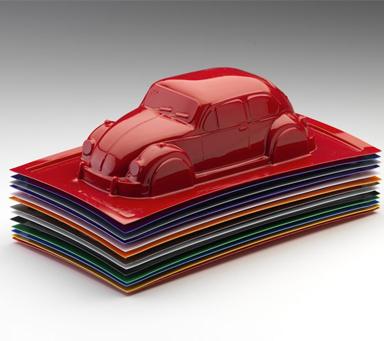

Vacuum Casting: Bridging Prototypes and Low-Volume Production

Vacuum casting is a brilliant technique for creating a small batch of high-quality copies from a master pattern. First, a master model (often made via CNC or 3D printing) is used to create a silicone mold. Then, a vacuum is used to draw a liquid polyurethane resin into the mold, producing bubble-free, highly detailed parts. This process is perfect for creating 10-50 units for market testing, trade show samples, or pre-production validation. It allows for a wide range of material properties, colors, and finishes, effectively simulating injection-molded parts without the massive investment in hard tooling.

The Tangible Benefits Beyond Just Speed

While accelerating speed to market is the headline benefit, the value of integrating rapid prototyping runs much deeper, influencing cost, risk, and the ultimate quality of the final product.

Significant Cost Reduction in the Long Run

The initial cost of a rapid prototype may seem like an added expense, but it delivers substantial savings over the entire project lifecycle. By identifying design flaws before committing to mass production tooling—which can cost tens or even hundreds of thousands of dollars—companies avoid catastrophic financial losses. Correcting a mistake in a CAD file is virtually free; modifying a hardened steel injection mold is a costly and time-consuming ordeal. Prototyping ensures the design is right *before* the major investment is made.

Mitigating Design Flaws and Manufacturing Risks

A design that looks perfect on a computer screen can reveal numerous unforeseen problems in the physical world. Parts might not fit together as expected (tolerance issues), a snap-fit might be too weak or too brittle, or an enclosure may be impossible to assemble on a production line. Physical prototypes allow for the early identification and resolution of these manufacturability (DFM) issues. This risk mitigation is crucial for ensuring a smooth transition from design to mass production and avoiding costly delays and product recalls.

Enhancing Product Quality and User Satisfaction

Better products are born from more iteration. By enabling multiple design cycles, rapid prototyping allows teams to continually refine and improve a product. Ergonomics can be perfected, usability can be tested, and aesthetic appeal can be fine-tuned based on real feedback. This iterative refinement leads to a more mature, robust, and user-centric final product. A higher-quality product translates directly to greater customer satisfaction, stronger brand reputation, and fewer warranty claims.

Integrating Rapid Prototyping into Your Workflow

Adopting rapid prototyping is more than just buying a 3D printer; it requires a strategic approach to integrating these technologies effectively into the product development process.

Selecting the Right Prototyping Method for Your Project

What is the best way to choose a prototyping technique? The answer depends entirely on the prototype's purpose. Is it for a quick visual check? Or for rigorous functional testing? Understanding the goal is key. The choice involves a trade-off between speed, cost, material properties, and fidelity.

Technology | Primary Advantage | Best For | Material Options |

3D Printing (SLA/SLS) | Speed & Geometric Complexity | Concept models, form/fit checks, intricate designs. | Photopolymers, Nylons, Resins. |

CNC Machining | Material Accuracy & Precision | Functional testing, high-stress applications, real-material feel. | Metals (Aluminum, Steel), Engineering Plastics (ABS, PC). |

Vacuum Casting | Low-Volume Duplication | Marketing samples, small batch runs, pre-production testing. | Wide range of Polyurethane resins simulating production plastics. |

Partnering with a Prototyping Specialist

For most companies, maintaining an in-house department with the full spectrum of prototyping technologies is not feasible. Partnering with a dedicated rapid manufacturing service provider, like Boen Rapid, offers access to a vast array of cutting-edge equipment and, more importantly, deep expertise. A specialist partner can provide invaluable guidance on material selection, process optimization, and design for manufacturability. This collaborative approach allows your team to focus on what they do best—designing innovative products—while leveraging the partner's specialized capabilities to bring those designs to life quickly and cost-effectively, securing that all-important speed to market.