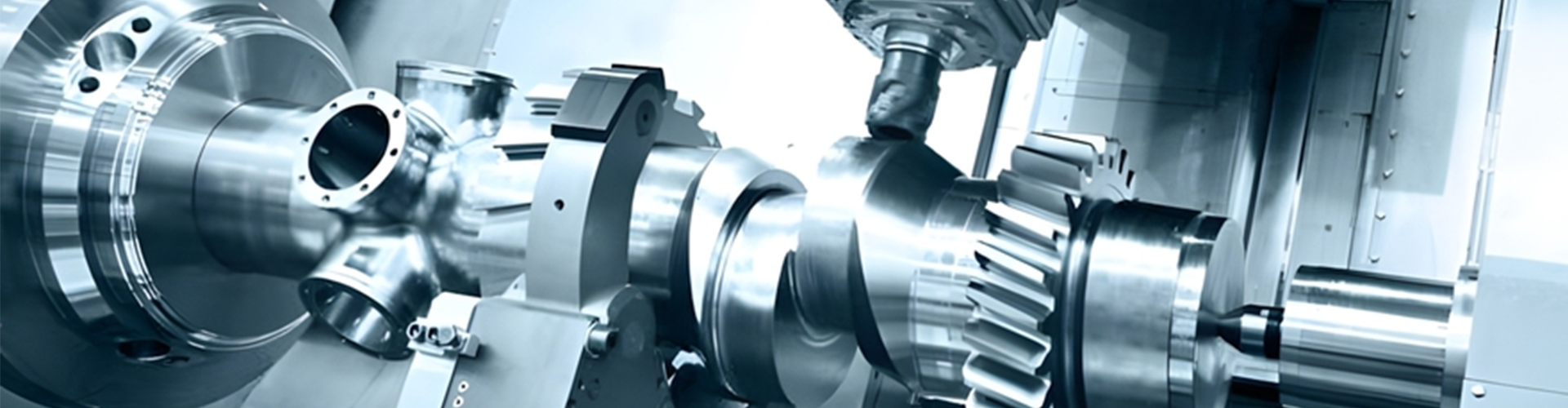

A 3-5 axis CNC machine is an advanced subtractive manufacturing tool that uses computer numerical controls to move a cutting tool or a workpiece along three to five different axes simultaneously. This capability allows for the creation of exceptionally complex shapes and geometries with superior precision and surface finish in a single setup, making it the cornerstone of modern precision manufacturing.

Table of Contents

1. What Defines CNC Machining and Its Evolution?

2. How Do 3-Axis and 5-Axis Machining Fundamentally Differ?

3. Why is 5-Axis Machining a Game-Changer for Complex Geometries?

4. What Are the Core Benefits of Adopting Multi-Axis Technology?

5. Which Industries Are Being Revolutionized by 5-Axis Precision?

6. Navigating the Challenges and Considerations of Advanced Machining

7. How Boen Rapid Leverages Advanced CNC for Superior Results

8. The Trajectory of Precision: What’s Next for CNC Machining?

What Defines CNC Machining and Its Evolution?

At its core, Computer Numerical Control (CNC) machining is a subtractive manufacturing process. It begins with a solid block of material (a "blank" or "workpiece") and systematically removes material using high-speed cutting tools to shape a final part. This entire process is directed by a pre-programmed computer code, often G-code, which dictates the tool's every movement, speed, and action with microscopic accuracy.

The Foundation: Understanding Computer Numerical Control

The concept of "numerical control" predates modern computers, but the integration with digital technology revolutionized the manufacturing floor. Instead of manual adjustments by a skilled machinist for every cut, CNC technology automates the process. A CAD (Computer-Aided Design) model is translated into CAM (Computer-Aided Manufacturing) software, which generates the toolpaths. This digital instruction set ensures that every part produced is identical to the last, achieving a level of repeatability and precision that is impossible to replicate by hand. This automation is the bedrock of modern mass production and rapid prototyping.

The Leap from 2-Axis to 3-Axis Operations

The earliest CNC machines operated on two axes (X and Y), similar to a plotter, suitable for simple profiles and cuts. The introduction of the third axis, the Z-axis, was a monumental step forward. This allowed the cutting tool to move up and down, enabling the carving of 3D shapes and pockets. 3-axis machining became the industry standard for a vast range of parts, from machine brackets to enclosures. It is highly effective for parts that can be machined from one side at a time, establishing the foundation for the more complex multi-axis systems to come.

How Do 3-Axis and 5-Axis Machining Fundamentally Differ?

The distinction between 3-axis and 5-axis machining lies in the degrees of freedom. While both are powerful, the additional two axes in a 5-axis system open a new dimension of manufacturing possibilities, directly impacting complexity, efficiency, and quality.

The Workings of 3-Axis Machining (X, Y, Z)

In 3-axis machining, the cutting tool moves along three linear axes: left-to-right (X-axis), front-to-back (Y-axis), and up-and-down (Z-axis). The workpiece remains stationary in a vise or fixture. This setup is perfect for drilling, milling flat surfaces, and creating relatively simple 3D contours. However, for parts with deep cavities or features on multiple faces, the part must be manually rotated and re-fixtured for each new orientation, a process that introduces time, cost, and potential for error.

The Multi-Dimensional Advantage of 5-Axis Machining (X, Y, Z + A, B/C)

5-axis machining builds upon the three linear axes by adding two rotational axes. These axes, typically designated A and B (or C), allow the workpiece or the cutting head (or both) to rotate. This motion, much like the dexterity of a human wrist, enables the cutting tool to approach the workpiece from virtually any angle. This capability is what allows for the machining of incredibly complex geometries, undercuts, and sweeping curves in a single continuous operation without the need to re-clamp the part. There are two primary types: 3+2 axis (or indexed 5-axis) machining, where the part is locked in a tilted position for 3-axis operations, and continuous 5-axis machining, where all five axes move simultaneously for creating smooth, complex contours.

Feature | 3-Axis CNC Machining | 5-Axis CNC Machining |

Axes of Motion | X, Y, Z (Linear) | X, Y, Z (Linear) + A, B/C (Rotational) |

Part Complexity | Simple to moderately complex; prismatic shapes. | Highly complex, organic shapes, deep pockets, and undercuts. |

Setups Required | Multiple setups for parts with features on different faces. | Often a single setup ("done-in-one"). |

Surface Finish | Good, but can show "scalloping" on contoured surfaces. | Superior, as the tool can maintain an optimal angle to the surface. |

Ideal Applications | Brackets, housings, plates, simple molds. | Turbine blades, impellers, medical implants, complex molds. |

Why is 5-Axis Machining a Game-Changer for Complex Geometries?

The ability to machine a complex part from start to finish without manual intervention is the primary reason why 5-axis technology is shaping the future of manufacturing. It fundamentally alters the approach to part design and production efficiency.

Machining Intricate Parts in a Single Setup

Consider an aerospace part like a turbine blade, which features complex, continuously changing curves. With 3-axis machining, producing such a part would require dozens of different setups, specialized fixtures, and would be prone to "tolerance stacking"—where small errors from each setup accumulate into a significant deviation in the final product. With continuous 5-axis machining, the tool can follow the blade's organic contour in one fluid motion, resulting in a perfectly formed part that matches the digital model with extreme fidelity. This "done-in-one" approach is not just a convenience; it's an enabling technology for designs that were previously unmanufacturable.

Eliminating the Need for Multiple Fixtures

Every time a part is unclamped, rotated, and re-clamped, there are costs involved. These include the labor to perform the setup, the time the machine sits idle, and the engineering and fabrication of custom fixtures. More importantly, each new setup introduces a risk of misalignment, however slight. 5-axis machining drastically reduces or eliminates these intermediate steps. By consolidating operations, it streamlines the entire production workflow, minimizing points of failure and ensuring that the first part is as accurate as the last.

What Are the Core Benefits of Adopting Multi-Axis Technology?

Beyond handling complex geometries, the move to 5-axis machining delivers tangible improvements in quality, speed, and cost-effectiveness that benefit a wide range of manufacturing projects.

Achieving Superior Surface Finishes

In 3-axis contouring, a ball-end mill often creates tiny, step-like ridges on a curved surface, known as scalloping, which may require secondary polishing. In a 5-axis operation, the tool can be tilted to maintain a tangential orientation to the part's surface. This allows for a wider section of the cutting tool to engage with the material, creating a much smoother, higher-quality surface finish directly off the machine. This reduces or eliminates the need for time-consuming and costly manual post-processing.

Drastically Reducing Lead Times and Costs

While the initial investment in a 5-axis machine is higher, the total cost per part is often lower for complex components. The reduction in setup time means machines are cutting for a higher percentage of the day. The elimination of custom fixtures saves engineering and fabrication costs. Shorter, more rigid cutting tools can be used because the head can be tilted to avoid collisions, allowing for higher cutting speeds and feeds. These efficiencies compound to significantly shorten the total production lead time from days or weeks to mere hours.

Enhancing Overall Part Accuracy and Consistency

Accuracy is paramount in precision manufacturing. By machining a part in a single clamping, 5-axis technology eliminates the cumulative errors associated with multiple setups. The part's relationship to the machine's origin point remains constant throughout the entire process, ensuring all features—holes, pockets, and surfaces—are perfectly located relative to one another. This guarantees the highest level of dimensional accuracy and part-to-part consistency.

Which Industries Are Being Revolutionized by 5-Axis Precision?

The capabilities of 5-axis machining are not just theoretical; they are actively driving innovation in the world’s most demanding sectors, where complexity and precision are non-negotiable.

Aerospace and Defense: Crafting Critical Components

The aerospace industry was an early adopter and continues to push the limits of 5-axis technology. It is essential for manufacturing components like blisks (bladed disks), impellers, structural airframe elements, and landing gear components. These parts are often made from tough superalloys like Inconel or titanium and feature complex aerodynamic profiles that demand absolute precision for safety and performance.

Medical Sector: Manufacturing Custom Implants and Devices

In the medical field, 5-axis machining is used to create patient-specific implants such as knee and hip replacements, dental prosthetics, and spinal fusion cages. These parts must match human anatomy perfectly and are often made from biocompatible materials like titanium and PEEK. The ability to machine organic, complex shapes makes 5-axis technology indispensable for creating life-changing medical devices and surgical instruments.

Automotive Industry: Prototyping and Production

From high-performance engine blocks and cylinder heads to intricate molds for interior components, 5-axis machining accelerates the automotive development cycle. It allows engineers to create and test functional prototypes with production-level quality in a fraction of the time. For low-volume and high-performance vehicles, it is also used for the direct production of lightweight, complex parts that enhance vehicle efficiency and performance.

Navigating the Challenges and Considerations of Advanced Machining

Transitioning to or utilizing 5-axis technology involves more than just acquiring the hardware. It requires a sophisticated ecosystem of software, skills, and strategic planning to fully harness its potential.

The Role of Advanced CAM Software and Skilled Programmers

The complexity of 5-axis toolpaths demands powerful CAM software capable of advanced simulation and collision avoidance. The software must accurately model the machine, the tools, the fixtures, and the workpiece to generate safe and efficient code. Furthermore, the skill of the CNC programmer and operator is critical. These professionals must have a deep understanding of machining principles, materials science, and kinematics to optimize setups and troubleshoot complex operations. The human element of expertise remains paramount.

Investment and Return on Investment (ROI) Analysis

A 5-axis CNC machine represents a significant capital investment compared to its 3-axis counterpart. Therefore, a thorough ROI analysis is essential. Businesses must consider not only the machine cost but also the software, training, and maintenance expenses. The return is realized through higher machine utilization, reduced labor per part, access to more complex and higher-margin jobs, and a significant competitive advantage in the marketplace. For many manufacturers, the ability to offer "done-in-one" solutions for complex parts justifies the investment many times over.

How Boen Rapid Leverages Advanced CNC for Superior Results

Successfully implementing this technology requires deep expertise and a commitment to quality. At Boen Rapid, we have integrated a sophisticated range of 3-5 axis CNC machining centers into the core of our operations. This investment in advanced machinery is not just about owning the equipment; it's about mastering the process to deliver unparalleled results for our clients across the aerospace, medical, and automotive industries. Our experienced team of engineers and programmers utilizes this technology to turn the most ambitious designs into tangible, high-precision parts.

Our approach focuses on leveraging the full spectrum of multi-axis benefits. By machining complex components in a single setup, we ensure the highest degree of dimensional accuracy and eliminate the risks associated with manual re-fixturing. This "done-in-one" methodology allows us to produce parts with superior surface finishes that often require no secondary processing, directly translating into faster lead times and greater cost-efficiency for our customers. Whether it's a rapid prototype or a low-volume production run, our 5-axis capabilities are a testament to our dedication to pushing the boundaries of manufacturing precision.

The Trajectory of Precision: What’s Next for CNC Machining?

The evolution of CNC machining is far from over. The future points toward even greater integration, intelligence, and capability. We are seeing the rise of hybrid manufacturing systems that combine additive processes (like 3D printing) and subtractive CNC machining within a single machine, allowing a part to be built up and then precision-finished in one continuous operation.

Furthermore, the integration of Artificial Intelligence (AI) and machine learning is set to optimize the manufacturing process even further. AI algorithms can analyze sensor data in real-time to adjust cutting parameters for optimal performance, predict tool wear to prevent failures, and automate quality inspection. As designs become more complex and demand for customized, on-demand parts grows, the intelligent, multi-axis capabilities of CNC machining will continue to be the engine driving the future of high-precision manufacturing.