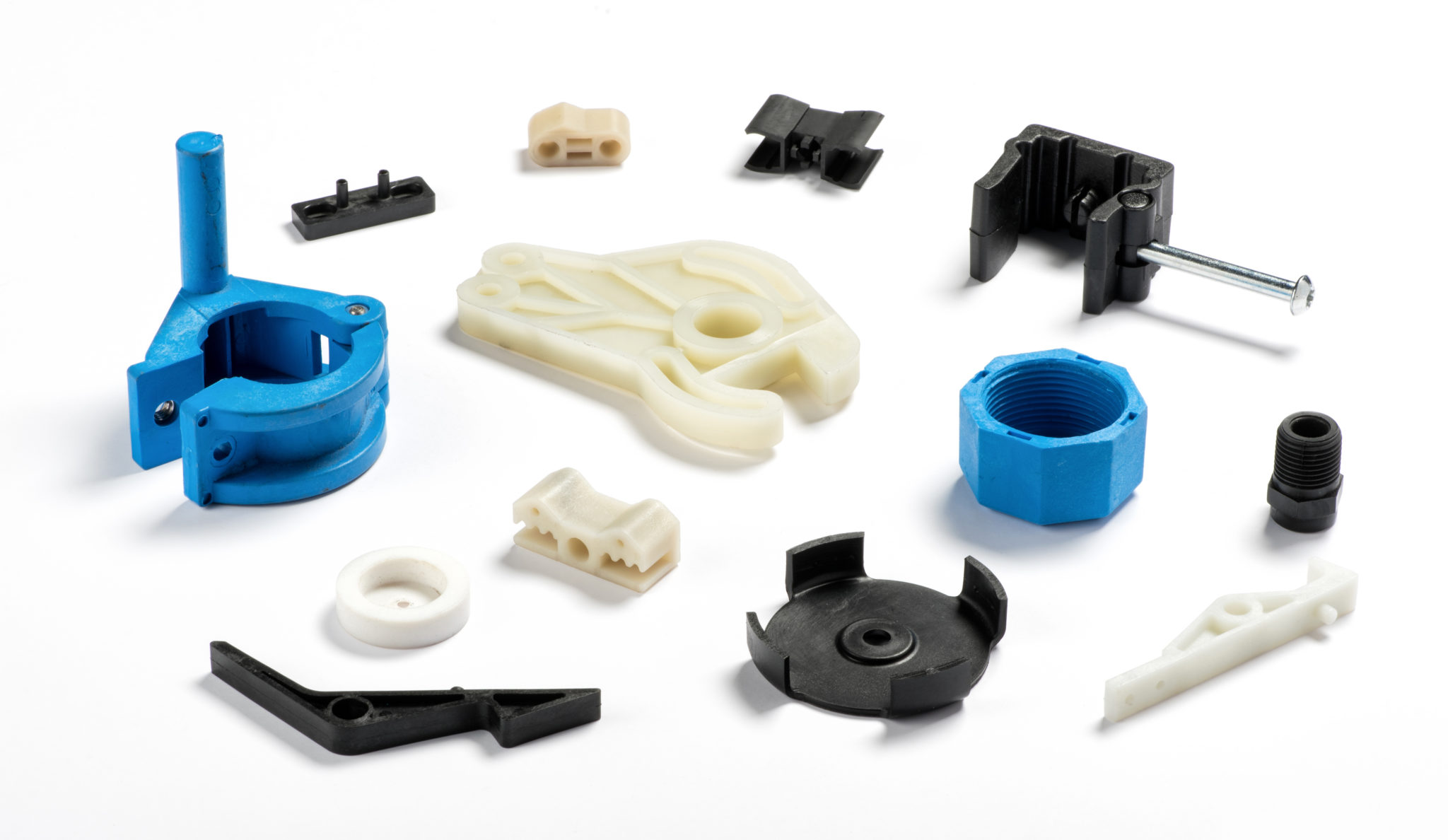

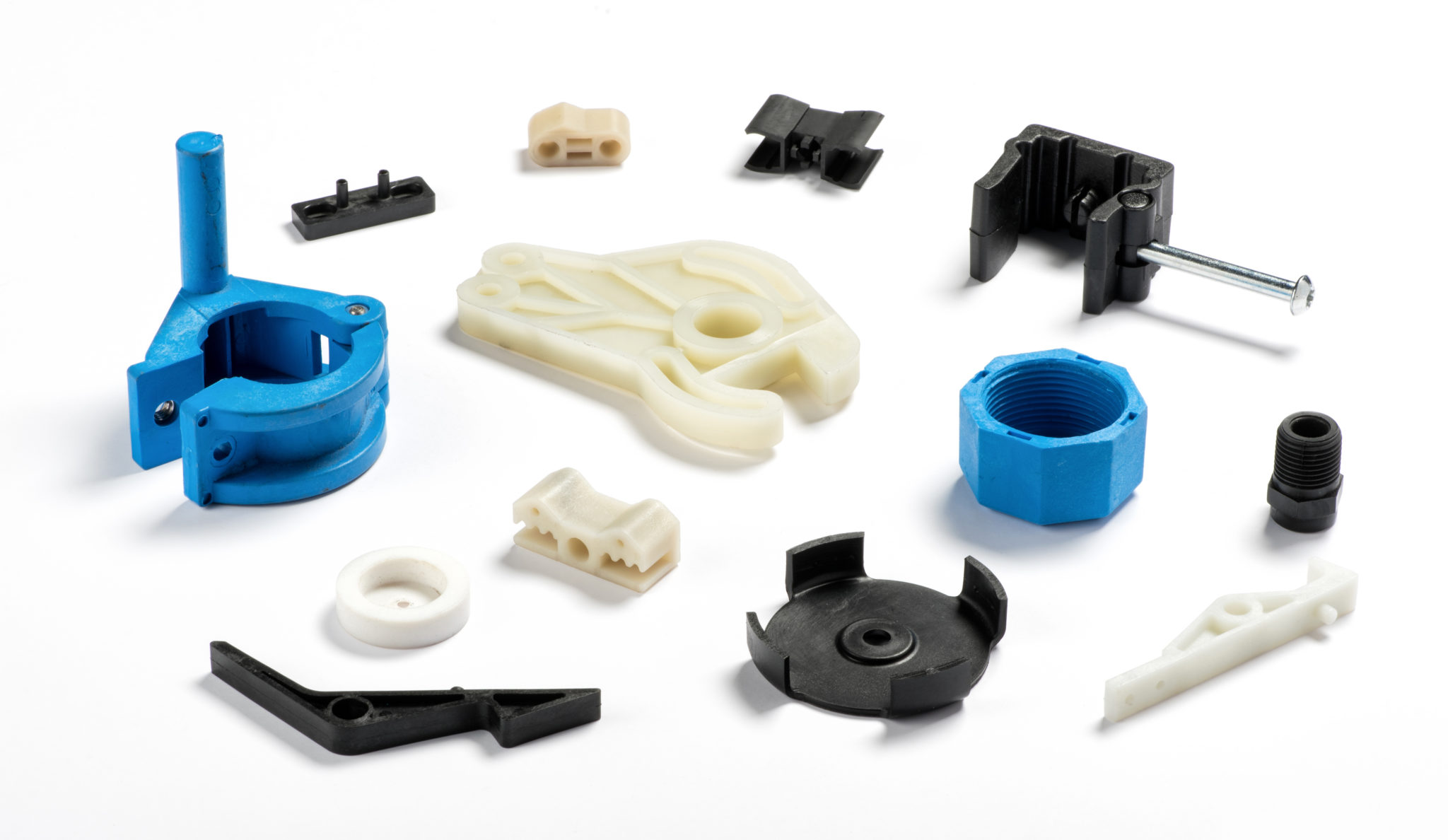

Injection molding is a manufacturing process that injects molten material, such as plastic, into cavities. It is typical in manufacturing high-volume healthcare, electronics, and automotive components. Overall, it gives intricate, durable, and precise parts with diverse advantages and disadvantages of injection molding.

For product developers and engineers, injection molding suits large-scale production. However, its disadvantages and advantages can influence machine time, costs, and product quality. This article uncovers the advantages and disadvantages of injection molding to help you achieve the highest return on investment.

How the Injection Molding Works

The first step involves the product developer assessing the injection molding setup to meet their setting's needs. The tech presents numerous benefits, like cost savings and efficiency in large-scale projects. However, it also has innumerable challenges, such as design limitations and high initial cost savings.

Therefore, you must understand the critical factors of injection molding to ensure optimal quality and flexible performance. This section unravels how it works to deliver the advantages and disadvantages of injection molding. Understanding these pros will help you identify and utilize opportunities with the procedure to attain quality.

1. Material Preparation

The material preparation stage marks the first step in the molding procedure, where developers melt plastic pellets into a molt. Overall, the pellets feature thermoplastic to allow heating and cooling without degradation. The process feeds the pellets into a heated barrel using a rotating screw to generate pressure.

In addition, the molten material features the apt viscosity to allow smooth flow and attain defect-free parts. Material selection helps achieve the product's appearance and maintain mechanical properties. You must understand that your material choice will likely impact your process costs. Thus, you must balance price and quality.

2. Injection

The injection process uses a specialized molding machine to inject the molten plastic into the cavities. Hence, the mold attains the exact specs of the final product to capture complex shapes and intricate details. Injection features high pressure to fill every mold corner and reduce incomplete fills and air bubbles.

The injection is crucial to attaining consistency and accuracy, but precision and speed determine the process efficiency in the large-scale production of complex parts. Hence, it can deliver advantages and disadvantages of injection molding. It is a critical stage that shapes the results and must be strategic and practical to attain good results.

3. Cooling

The molten material cools from the cavities to solidify and retain its shape. Overall, the cooling process is critical to achieving mechanical properties and dimensions. Depending on the complexity, it also helps to prevent shrinkage and warping. The cooling process relieves residual stress for a durable and robust product.

4. Ejection

Ejection removes the object from the mold cavity after it solidifies. This step can use ejector pins without damaging the object's structure. Thus, it demands precision to avoid deformation and damage. It renders the product ready for post-processing to attain the advantages and disadvantages of injection molding.

5. Finishing

The finishing stage involves surface treatments and trimming to ensure a perfect product. Overall, the trimming process removes excess material like flash and sprees. You can also opt for additional treatment options like texturing, coating, and painting to boost functionality and meet functional specifications and appearance.

Advantages of Injection Molding

The article covers numerous advantages and disadvantages of injection molding tech. Understanding how it works is essential for strategizing and leveraging features. This part discusses dimensional consistency, material diversity, auto production, and speed. Discover ideas to help you strategize your process based on these benefits.

1. High Production Efficiency

The injection molding technique features high production with low costs. The process can produce large-scale parts in a short period of about 20 to 60 seconds per object. In other words, it offers rapid production speed for manufacturers to attain high output in mass production. Besides, it decreases the per-unit cost but ensures consistent quality.

Although the tooling costs and initial setup can be high, the process offers substantial time, material, and labor savings in high-volume production. Therefore, manufacturers can deliver fast results through automation to reduce manual labor costs. This strategy can be a productive tool for ensuring consistent quality across large-scale tasks.

2. Mold Complex Shapes

It offers complex geometries and intricate designs with complex shapes, multiple cavities, and fine details. Hence, it produces products that would otherwise be impossible or challenging to craft. You can easily incorporate wall thickness, thread inserts, and undercuts due to the advantages and disadvantages of injection molding

.In other words, the procedure produces diverse products with extreme flexibility. It is a typical option for consumer electronics, auto parts, and medical tools. These industries leverage the flexibility of crafting complex shapes to produce products that require high precision. Overall, it complies with complex and exact geometries to deliver results.

3. Automated Production

The tech features automation to increase production speed and reduce labor costs. In addition, it relies on auto systems and robotics to reduce human intervention and ensure consistency. These auto tools minimize human error and speed and attain precise product specifications that suit complex settings like medical.

Overall, injection molding features high automation, allowing designers to maintain quality control and accuracy. It reduces costs and manual labor needs while ensuring the final products meet quality standards. Besides, reduced human intervention ensures fewer mistakes that would instead result in varying precision.

4. Wide Range of Material

The tech uses diverse thermoplastic materials with different features, such as chemical resistance, strength, and flexibility. Hence, it allows designers to select materials based on the project. Critical features include lightweight, heat resistance, and durability. Manufacturers choose each feature based on the application setting.

Overall, the molding process enables convenient features to be integrated into the products to eliminate costly coating or painting. It allows manufacturers to leverage the flexibility of textures, colors, and finishes, diversifying design ideas. Flexibility is a critical pro for excellent results in injection molding, regardless of the material.

5. High Dimensional Consistency

Injection molding can produce parts with repeatability and high precision. It suits niches that require dimensional consistency, such as aerospace and medicine. Hence, it can repeat the same production process on more objects without variation. Meanwhile, the tech meets strict quality standards and reduces defect risks.

Disadvantages of Injection Molding

On the other hand, despite the advantages and disadvantages of injection molding, the tech faces numerous drawbacks. These include the high cost of small batches, design restrictions, and high initial investment. This section comprehensively explains how these drawbacks impact your injection molding results.

1. High Initial Investment

A primary con of injection molding in manufacturing is the high upfront investment. Projects attract high costs for intricate designs, multiple cavities, and complex parts. The initial costs can be high for small firms to run low-volume tasks. Yet, once you install the technology, you can leverage diverse precision and efficiency.

2. Design Limitations & Restrictions

Injection molding allows you to create complex shapes but has design restrictions. For instance, the product must adhere to specific undercuts, draft angles, and wall thickness to fill the mold. The constraints might hamper creativity since failure to follow the specs results in incomplete fills, sink marks, and warping.

3. Unsuitability for Small Batches

The process allows manufacturers to save money in large-scale production processes. Low-scale prototyping produces more per-unit costs than CNC machining and 3D printing. Nonetheless, it can be an excellent option for small batches, focusing on cost efficiency, speed, and flexibility. Overall, it has high upfront costs.

Conclusion

Injection molding can be a strategic option for high production flexibility. It suits large-scale projects for cost-effectiveness and complex geometries. Yet, it has several challenges, like design limitations, long lead times, and high initial investment. Developers must weigh the advantages and disadvantages of injection molding.

Get Quality Injection Molding Today!

At BOEN, we specialize in providing innovative injection molding solutions tailored to meet the unique needs of engineers and product developers. With years of experience in the industry, we offer high-quality manufacturing services, advanced design support, and a commitment to excellence and ensuring quality results for our clients.

Our team of experts is dedicated to helping you bring your ideas to life and ensuring that your projects are completed on time and within budget. Above all, we are responsive and boast a track record of delivering consistent results on diverse projects. Contact us today to learn how we can assist you in your next injection molding project!