Email: contact@boenrapid.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- Services

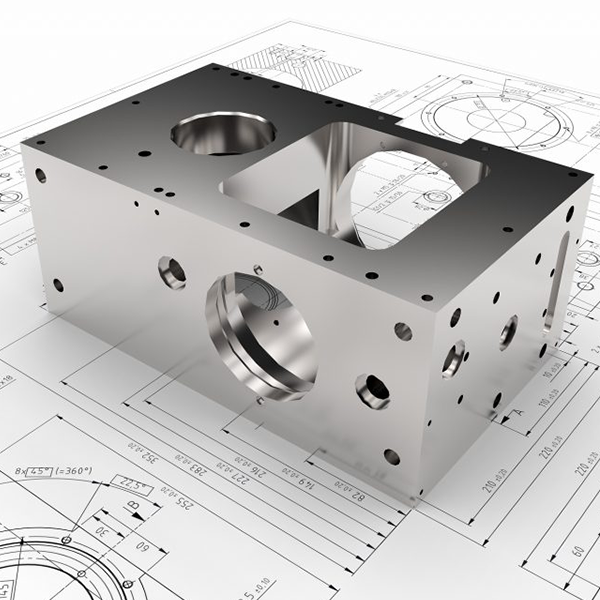

- Custom Parts Manufacturing

- Rapid Prototyping

- Low Volume Production

- 3-5 Axis CNC Machining

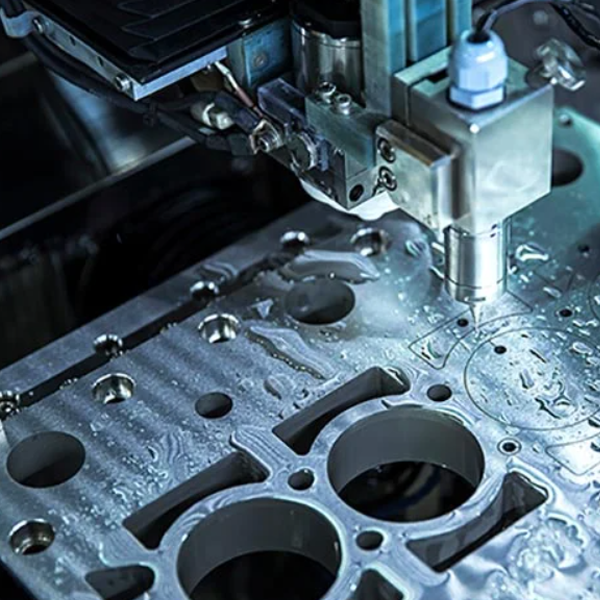

- CNC Milling

- CNC Turning/Lathing

- Sheet Metal Fabrication

- Vacuum/Urethane Casting

- RIM (Reaction Injection Molding)

- 3D Printing (Additive Manufacturing)

- Plastic Injection Molding

- Die Casting

- Aluminum excussion

- Wire EDM

- Industries

- Resources

- About Us

- Blog

- Contact Us